Many Kind of Plastic Glues:

Superglue can use for cars and trucks parts, but only a small part can use superglue to stick on the interior part of cars or trucks. Only plastic part can stick strong enough use this superglue but for other usage this glue is not recommended. Do you imagine that how about all the car part is use glue not using bolt and rivet, this may happen on cars and trucks toys. Car with high speed is impossible if just use glue on their parts, because with high speed, big vibration will make on the car and some splash of water or oil or even chemicals that stay on the road may come to your cars part and make it corrosive and make damage to the part. If only glue on the part to stick together usually will loose very soon. Superglue just may use of car and truck toys but for real car it is only use in small area.

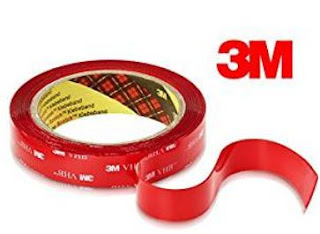

Glue for many toys like, cars and truck can use superglue, this toys may just for display only, for toys that can run fast, glue also sometime failure and loose their strength. For toys many glue can use like Superglue, power glue or other kind of plastic glue. Be careful on using this glue, you better use goggles to avoid any splash of glue to your eyes, and use rubber hands clove to avoid any glue to stick to your hand because it is can peeled up your skin if stick to your hand. There are many kind of

plastic glue can use for cars and trucks toys or other toys you have. For recommended plastic glue can see on the picture below:

|

| Plastic Glue |